Strainer Manufacturer in India

Speciality Valve . Follow

4 months ago

Speciality Valve takes pride as a premier Strainer Manufacturer in India, serving diverse regions like Maharashtra, Uttar Pradesh, and Kerala. In the realm of this context, a strainer is a vital pipe fitting employed for the purification, filtering, or separation of liquids from solid matter, effectively straining liquids from a device. Operating as a sieve or filter, it halts solid bodies from mixing in a liquid stream or flow line. The welded metal in pipelines shields appliances and processes from their harmful effects, thereby reducing both time and maintenance.

What is a Strainer?

A strainer is a device used to separate unwanted particles from a mixture, typically in a fluid or gas flow.

Working Principle of a Strainer: The working principle of the strainer is straightforward. Regardless of the type of strainer used, recognizing both the input and output is essential. Upon correct attachment, the fluid seamlessly flows through the filter housing into the suction section. The strainer catches all the flow and materials suspended into one place. Subsequently, the strainers block these particles:

- The fluid departs from the inlet and enters the basket strainer.

- The debris like soil, particles, and trash gets collected into the basket strainer.

- The pressure differential activates the warning once prevention occurs.

- The strainer design allows the option to either shut down the pipe mechanism or direct the flow to the next basket strainer.

Type of Strainers:

- Duplex Basket Strainer: Offers continuous filtration with dual baskets, ensuring uninterrupted operation and easy maintenance.

- Simplex Basket Strainer: Provides effective straining with a single basket, suitable for applications where periodic maintenance is feasible.

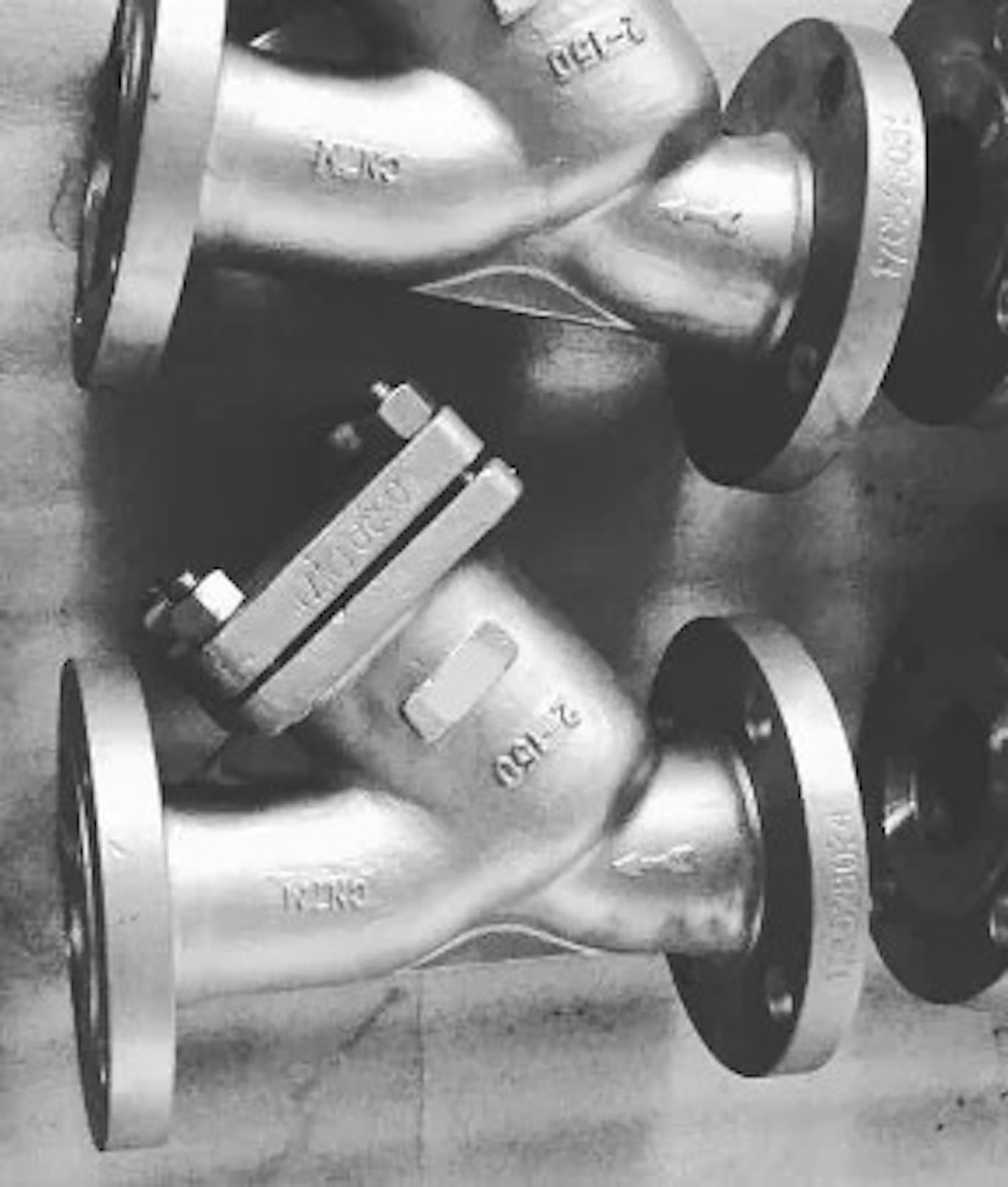

- Y Strainer: Utilizes a Y-shaped configuration for efficient filtration, commonly employed in pipelines to strain out unwanted particles and debris.

Key Features of Strainer:

- Material Selection: Strainers are available in a variety of materials, including stainless steel, carbon steel, bronze, and exotic alloys, to suit different operating conditions and fluid compatibilities.

- Design Variations: Strainer valves come in various configurations, including Y-type, basket, and duplex designs, each tailored to specific applications and flow requirements.

- Pressure Ratings: Strainers are designed to withstand varying pressure levels, with options available for low-pressure systems as well as high-pressure applications.

- Screen/Mesh Options: The choice of screen or mesh size depends on the desired level of filtration and the size of particles to be captured.

Advantages of Our Manufactured Strainer:

- Low resistance value

- Large effective filtering area

- Simple operation

- High degree of filtering flexibility

- Wide range of uses

Industrial Usage of Strainer:

- Oil and Gas Industry: Essential for protecting sensitive equipment and components from contaminants in fluid systems.

- Chemical Manufacturing: Ensures the purity of chemicals by filtering out solid particles and impurities during the manufacturing process.

- Petrochemical Industry: Safeguards pipelines and equipment from debris, contributing to the efficiency and longevity of petrochemical processes.

- Water Treatment and Wastewater Management: Plays a crucial role in filtering water and wastewater, maintaining the integrity of treatment systems and protecting downstream processes.

- Power Generation (including nuclear, coal, and natural gas): Protects turbines and other equipment by preventing debris from entering, ensuring efficient and reliable power generation.

- Pulp and Paper Industry: Vital for preventing clogging in pulp and paper processing, improving overall operational efficiency.

- Mining and Minerals Processing: Filters out solid particles in mining processes, preventing equipment damage and ensuring smooth operation.

- Marine and Shipbuilding: Used to filter seawater and other fluids in marine systems, contributing to the longevity of ship components.

- Textile Industry: Helps maintain the quality of process water, safeguarding textile manufacturing equipment.

- Automotive Manufacturing: Ensures the cleanliness of fluids used in manufacturing processes, protecting precision components.

- Aerospace Industry: Filters out contaminants from fluids used in critical aerospace applications, ensuring reliable operation.

Strainer Manufacturer in India offers a diverse range of strainer products with variations in design, straining components, size, flow capacity, and maintenance requirements.

Description:

- Available materials: WCB, WC6, WCC, LCB, LCC, CF8, CF8M, cast iron, SS304, SS316, ductile iron, Carbon steel (ASTM A105, ASTM A516), Stainless Steel (ASTM A182 F304, ASTM A182 F316), Brass (ASTM B16, ASTM B124)

- Class: 125 to 300

- Nominal Pressure: PN6 to PN25

- Size: ½” to 32”

- Ends: Flanged, threaded, Buttweld, socket weld

Visit us: https://www.specialityvalve.com/product-category/strainer/