Understanding the Applications and Benefits of Pole Band Clamp

swati . Follow

4 weeks ago

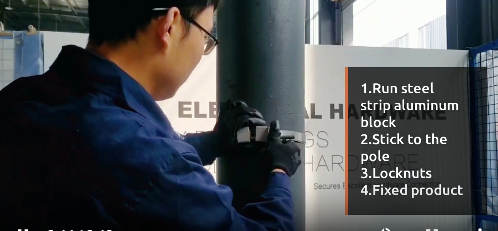

Pole Band Clamps: Securing Components to Utility Poles

Pole band clamp is essential device used in utility infrastructure to secure various components to utility poles. Typically, these clamps are metal bands that tightly encircle the pole, providing a secure attachment point for hardware such as cross arms, brackets, or other utility fittings. Without these clamps, the reliability and stability of power lines would be compromised.

-

Purpose and Functionality: Pole band clamps are designed to hold equipment like transformers, communication cables, or electrical conductors onto wooden or metal utility poles. These clamps are known for their strength and flexibility, allowing them to support a variety of loads. Tightening the clamp around the pole ensures that the attached hardware remains stable and can withstand environmental stresses like wind, vibration, and weight.

-

Materials and Durability: Pole band clamps are usually made from corrosion-resistant materials. These materials ensure the clamp can endure harsh outdoor environments, including exposure to rain, humidity, and temperature fluctuations. Durability is key in preventing equipment failure or detachment from the pole.

-

Applications in Utility Systems: These clamps are used across different utility applications, including electricity distribution and telecommunications. They are essential in rural and urban settings where utility poles must carry heavy loads, ensuring equipment remains in place for years without frequent maintenance.

Conductor Termination Dead Ends: Securely Anchoring Power Lines

Conductor termination dead end, or dead-end clamps or fittings, are critical in terminating or anchoring overhead conductors. These fittings ensure the safe and secure attachment of power lines to poles or towers, providing the necessary tension to keep the lines stable and well-supported.

Purpose and Functionality: The primary role of a conductor termination dead end is to create a secure, permanent connection point where an overhead conductor is anchored. It distributes the tension evenly across the conductor, preventing sagging and ensuring the line remains in place under various loads and weather conditions. This is especially important in high-tension power lines, where the weight and tension can be immense.

Types of Conductor Termination Dead Ends: Dead ends come in several different forms depending on the application. Some common types include:

-

Compression Dead Ends: Used in high-tension environments where a permanent, solid termination is required. The conductor is crimped inside the dead-end fitting, ensuring a long-lasting connection.

-

Helical Dead Ends: These use preformed helical rods that grip the conductor tightly. They are common in medium-tension lines and are easier to install than compression dead ends.

-

Wedge Dead Ends: Consisting of a wedge that tightens around the conductor, these dead ends are often used for temporary or adjustable applications.

Importance in Power Line Stability: A conductor termination dead end not only secures the conductor but also helps to maintain proper tension, preventing the lines from sagging or swaying excessively. This is crucial for ensuring continuous and reliable power delivery, as sagging lines could lead to power outages, equipment damage, or even safety hazards for nearby residents.

Plastic Side Ties: Protecting and Guiding Conductors

Plastic side tie is crucial in securing conductors to insulators on utility poles. These ties serve the dual purpose of holding the conductor in place while providing flexibility and protection against wear and tear, particularly in high-stress environments where the conductor may experience movement due to wind or other forces.

Purpose and Functionality: Plastic side ties are used primarily in overhead power distribution systems to secure the conductor to the top of the insulator on a utility pole. Unlike traditional metallic ties, plastic side ties are more flexible, which allows for slight movement of the conductor without causing damage to the wire or the insulator. This flexibility is essential in areas with high wind or frequent vibrations.

Materials and Advantages: These ties are typically made from high-strength, UV-resistant plastic materials. The use of plastic offers several advantages over metal alternatives:

-

Corrosion Resistance: Plastic ties do not corrode, making them ideal for use in coastal or highly humid areas.

-

Lightweight: Plastic side ties are lighter than their metal counterparts, making installation easier and reducing the overall weight load on the pole.

Installation and Performance: Plastic side ties are relatively easy to install and often snap or twist around the conductor and insulator. This simplicity speeds up the installation process and reduces the labor required. Once in place, they reliably secure the conductor while minimizing damage to the wire’s outer covering. Additionally, plastic side ties can be used with vibration dampers to protect the conductor from mechanical stresses further.

Applications and Industry Use: Plastic side ties are commonly used in medium-voltage power distribution systems and some telecommunications applications.

The Role of These Components in Modern Utility Infrastructure

Integrating pole band clamps, conductor termination dead ends, and plastic side ties in utility systems highlights the need for reliable, durable components in maintaining infrastructure. These components play distinct yet interrelated roles in ensuring that utility lines are securely attached to poles, adequately tensioned, and protected from environmental and mechanical stresses.

-

Ensuring Longevity and Reliability: By choosing high-quality materials and designs, these components help extend the lifespan of utility infrastructure. Strength, flexibility, and resistance to corrosion are essential qualities that enable them to endure challenging conditions and carry on without regular replacement or repair.

-

Enhancing Safety: Properly securing conductors and other utility equipment is vital for ensuring public safety. A poorly maintained or unstable power line can pose significant risks, from electrical hazards to potential fires. Using components like pole band clamps, conductor termination dead ends, and plastic side ties helps mitigate these risks.

Conclusion

In the world of utility infrastructure, components like pole band clamps, conductor termination dead ends, and plastic side ties play critical roles in maintaining the safety and reliability of power and communication lines. Each component has a specific function, from securing hardware to managing tension and protecting conductors from wear. We can better appreciate the intricacy of the architecture that drives our everyday lives if we recognize the significance of these elements. By investing in durable, high-quality materials and components, utility providers can ensure the longevity and safety of their systems while minimizing maintenance costs and downtime.

Recommended topics

Recommended from Guest Post

Amelia Emily

Custom Dropper Bottle Boxes: A Packaging Solution That Fits Your Brand

September 16, 2024

Modern European Custom Cabinetry Arizona

Why Choosing a Local Cabinet Maker in Tucson Makes All the Difference

August 26, 2024Tonia Carver